Acoustic Louvres

QEF offers a range of aluminium acoustic louvres with two blades designs in various configurations.

AC100 Single Bank Acoustic Louvre

QEF AC100 Single Bank Acoustic Louvre, extruded aluminium louvre blades, polyester fill, mounted on mullion/clip support system. Rw 9 Rating.

AC100 Double Bank Acoustic Louvre

Double Bank Acoustic Louvre, extruded aluminium louvre blades, polyester fill, mounted on mullion/clip support system, louvres back to back. Rw 14 Rating.

AC150 Single Bank Aluminium Acoustic Louvre

Single Bank Aluminium Acoustic Louvre, continuous line, folded aluminium blades, polyester fill, mounted on mullion/ clip support system. Rw11 Rating.

AC150 Double Bank Acoustic Louvre

QEF AC150 Double Bank Acoustic Louvre, continuous line, aluminium blade, polyester fill, mounted on mullion /clip system, back to back. Rw17 Rating.

AC 150 Vertical Aligned Double Bank Acoustic Louvres

Louvre blades are aligned vertically to achieve a higher weathering classification whilst retaining the same acoustic and airflow characteristics. Rw 17 Rating.

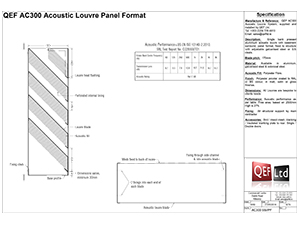

Acoustic 300 Single Bank Louvres

Single Bank Aluminium Acoustic Louvre, panel format, folded aluminium blades, polyester fill. Rw17 Rating.

Acoustic 300 Double Bank Louvres

Double Bank Acoustic Louvre, extruded aluminium louvre blades, polyester fill, mounted on mullion/clip support system, louvres back to back. Rw 28 Rating.

Louvre Design

Traditionally, acoustic louvres are of pressed metal fabrication from pre-galvanised steel sheet, with

mineral wool acoustic fill, supplied as assembled panels.

QEF offers two acoustic louvre blade designs in various configurations:-

QEF AC100 Acoustic louvres

• Extruded aluminium blade and a perforated aluminium acoustic fill support.

• Polyester Blend acoustic fill as standard, optional blend with added Fire Retardant fibres to achieve BS EN 13501-1 Class B available.

• Single bank or double bank arrangements.

• Mounting on a mullion /clip system as standard for large format continuous line applications, or as assembled panels for small liftable units.

• Supplied with casement surrounds, flanges, drips or glazing inserts as required.

• Single or double doors either integrated into larger QEF AC100 louvres or as standalone units.

• Aluminium components powder-coated to Qualicoat standard.

QEF AC150 Acoustic louvres

• Folded aluminium blades and perforated aluminium acoustic fill support.

• Polyester Blend acoustic fill as standard, optional blend with added Fire Retardant fibres to achieve BS EN 13501-1 Class B available.

• Single bank or double bank horizontal louvre arrangements.

• Double Bank louvre with acoustic louvre blades in the vertical to offer improved weathering.

• Mounting on a mullion /clip system as standard for large format continuous line applications, or as assembled panels for small liftable units.

• Supplied with casement surrounds, flanges, drips or glazing inserts as required.

• Single or double doors either integrated into larger QEF AC150 louvres or as standalone units.

• Aluminium components powder-coated to Qualicoat standard.

Acoustic fill

The acoustic fill used in traditional acoustic louvres has been mineral/ rock wool with a tissue face to limit

the migration of loose fibres.

QEF have made the decision to avoid the use of mineral/ rock wool due to the health and safety issues arising during the manufacturing process in the first instance. Secondly, the use of mineral/ rock wool in certain facilities is becoming more restrictive due to the potential risk of fibre migration.

QEF has chosen to use Polyester Blend acoustic fill for our acoustic louvres as it offers significant

advantages, namely:

• Non-irritant & non-itch material that is free from floating fibres or dust and so avoids skin irritation and respiratory problems normally associated with other forms of insulation

• User-friendly- no protective clothing required by users

• No concerns regarding it being a Group 2B Carcinogen

• Moisture tolerant – no concerns with moisture affecting thermal or acoustic properties

• Mould resistant

• Manufactured from 75% recycled material

• Fully recyclable

The Major Advantages:

• All components 100% recyclable, Polyester fill made from 75% recycled material.

• Acoustic performance data backed by certified test reports from SRL for acoustic performance and BSRIA for airflow and weathering performance.

• Louvre of any size will be a true continuous line louvre, with no vertical panel frame joints.

• The use of extruded aluminium louvres creates an aesthetically pleasing louvre for important architectural facades.

• Louvres delivered to site in kit-form for site assembly, reducing transport costs and eliminating cranes to lift the traditional assembled panels into place.

• All aluminium components powder-coated to Qualicoat standard with full pre-treatment, not available with traditional pressed metal systems.